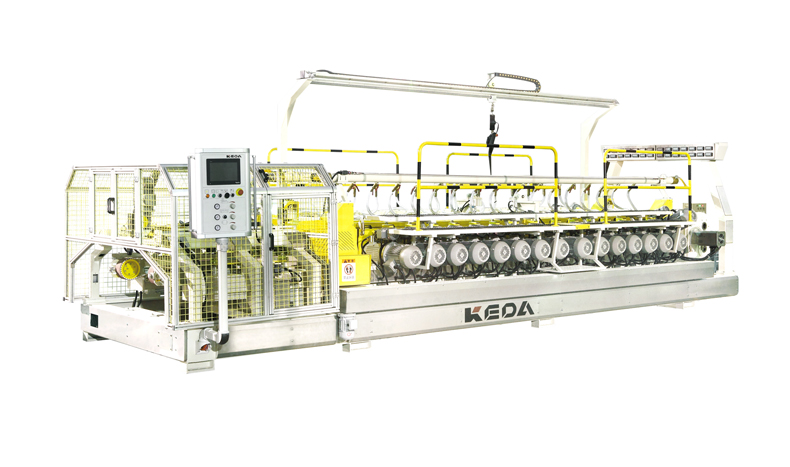

NC squaring & chamfering machine series

Basing on internet + and internet of things technology. Integrateing automatization, informatization and intelligentization.

² Fewer operators, lower skill requirement for operators, improved working condition.

² Touch screen operation for HMI. High performance PLC control.

² KD358 series electric feed squaring head with high precision and stable running.

² Auto warning before squaring wheel worn out. Free squaring wheel replacement without machine stoppage.

² Double servo is optional for main drive, easy belt replacement and high synchronization precision.

² Motorized servo control for the tile pushing claws, safety and high precision.

² Digital controlled auto working width regulation.

² Energy management system, auto-calculate power consumption, generate energy consumption report.

² Equipment management system: In-built operation manual and spare parts manual, lubrication reminding, auto count equipment utilization rate, maintenance and parts replacement saving functions.

² Production management system: save and call parameters, easy to switch production. Auto-count output, abrasives consumption, preinstall ports with dimension measuring unit, auto generate production and quality reports

² Patent right of upper monitor software for real time communication; adopts standard internet interface, seamless access to factory LAN, two-way communication with ERP (MRP, OA) software.

² Remote monitor software, preinstall network interface, remote real time control, remote operation (optional).

² New industrial design appearance; water fog proof and new antirust paint technology; comply with CE and UL safety and environmental protection standard.

² Separated soundproof room is optional.

Integrated dry and wet Squaring design; add dust collector system for dry squaring.