Recently, the intelligent brick storage system before packaging and new large slab automatic packaging line offered by KEDA Ceramic Machinery have been successfully commissioned at the new production facility of Guangdong YUHUI Ceramic Group's second workshop. The project has received high praise from the customer.

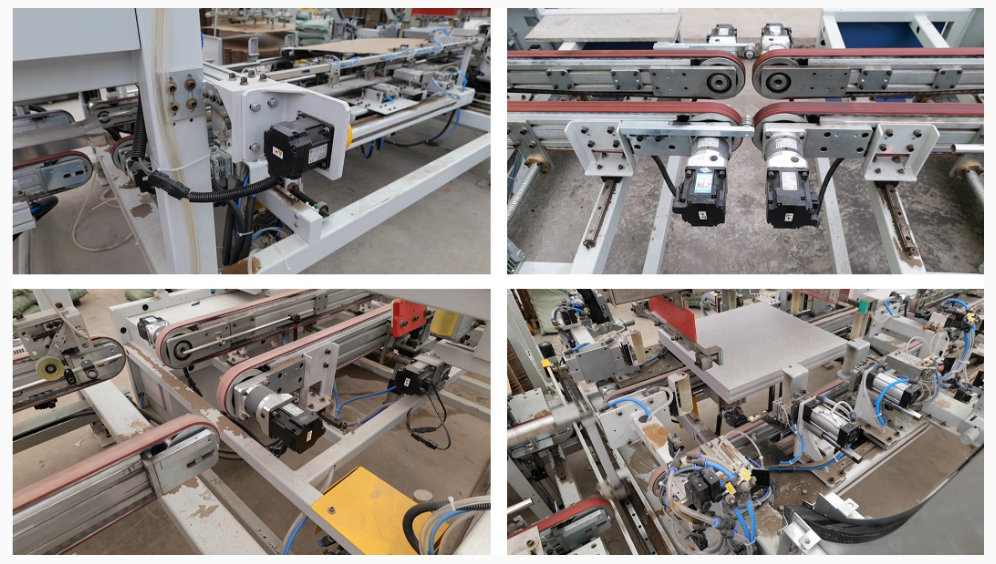

These two packaging lines are designed to produce high-end large slab products with dimensions of 600×1200 (mm), 750×1500 (mm), and 900×1800 (mm). The complete production line operates at a stable speed of over 10 packages per minute, with the daily single-line output exceeding 27,000 m², fully satisfying the customer's production requirements.

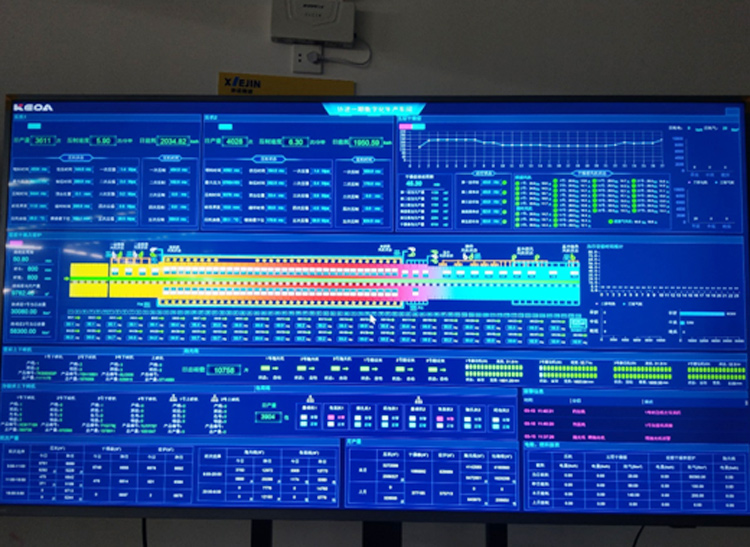

After introducing KEDA's two new packaging lines, there have been significant improvements in several areas. The new models have enhanced the aesthetic appeal of the machinery. They also offer better packaging speed, improved specification compatibility, and greater operational stability compared to the old models. Additionally, this packaging line, paired with KEDA intelligent brick storage system's digital display system, visually presents important information such as product color, batch, and output, greatly facilitating production organization," praised the YUHUI production manager.

This year, KEDA Packing Machinery Division has restructured its product line, focusing on product customization and standardization of optional configurations to meet the demand for rapid delivery. While ensuring a balance between speed and stability, the company continues to enhance the functionality of its machinery, providing more competitive products and creating greater value for customers. Through continuous innovation, KEDA is leading the advancement of industry technology.

Established in 2006, YUHUI Ceramic Group operates 3 production bases with 5 large-scale production lines, boasting an annual output of over 60 million m². Since its inception, the company has invested heavily in high-end production machinery, building a robust production capacity and strictly ensuring product quality, thereby laying a solid foundation for the brand's future development.

Centralized control system

Centralized control system Advantages

Advantages

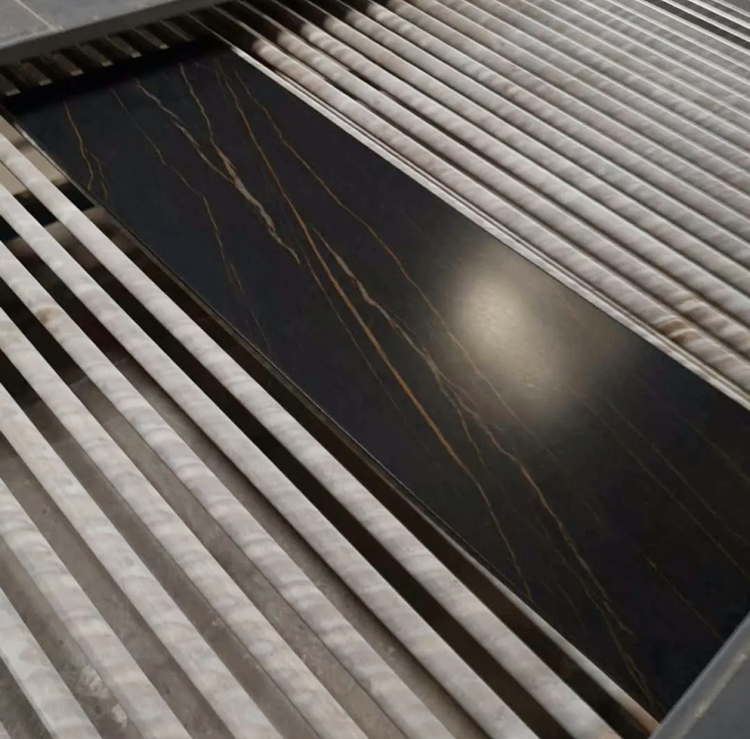

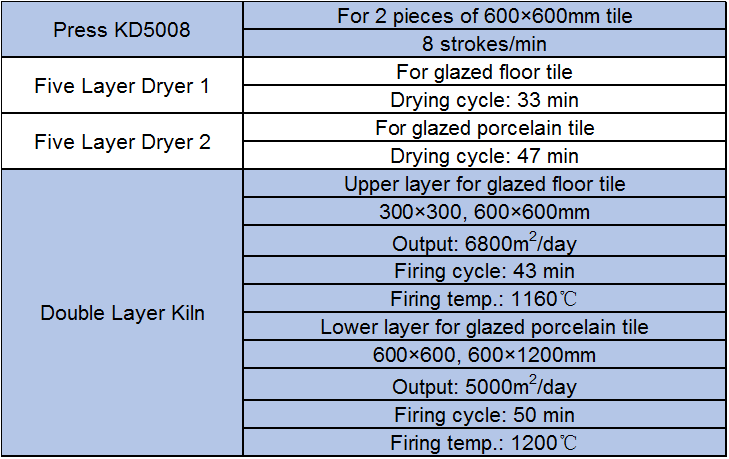

Highlight of Double-layer roller kiln

Highlight of Double-layer roller kiln Highlight of Press KD5008

Highlight of Press KD5008

Smart control system

Smart control system 30% labour force reduced

30% labour force reduced SRS fume exchange system

SRS fume exchange system

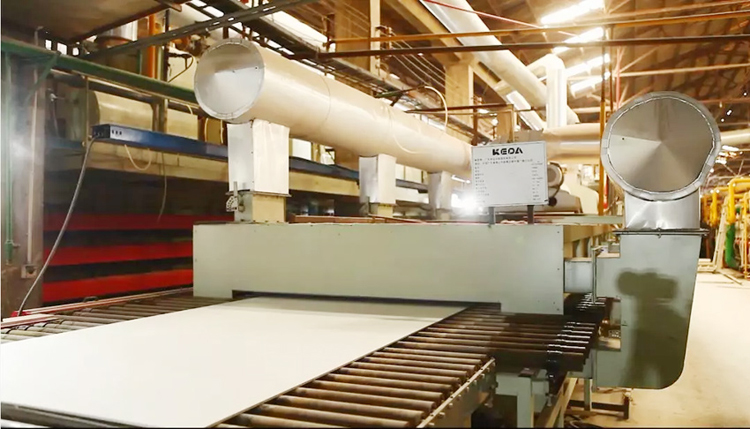

The first 3.2m wide kiln for the rock slab in the world.

The first 3.2m wide kiln for the rock slab in the world. Innovative technology helps to offer the solution for the slab crack settling during cutting.

Innovative technology helps to offer the solution for the slab crack settling during cutting.